Winding machines for bobbins

Swiss quality

IBA Machinery Ltd. acquired Casati Carlo AG together with its 80 year old know how developing and producing accessories for the textile industry. We are specialized in manufacturing machines for the production of high quality winding machines for bobbins, where our main products are SIGMA II and ECCO II.

We also offer various accessories to support the production of perfect bobbins. With us you can get everything from one source, starting from consulting on all questions around bobbins to know how in regards to the mechanics, electronics, sales and trainings on servicing. At our plant in Berneck, at the heart of the Swiss Rhine valley, the two winding machines originate that are utilized all around the world.

Perfect bobbins, for embroidery

Thanks to our years of expertise, we offer our clients unparalleled customer service — round the clock.

Machine SIGMA II

SIGMA II is the only bobbin winder in the world computer monitoring the quality of every single bobbin produced. It produces top quality bobbins even faster and, at lower cost then conventional machines. Each bobbin has the same length. True to the meter. Resulting in a equal run-out of the bobbins in the shuttle of your embroidery- or quilting machine. Your advantage: more money, less downtime, less personnel and less scrap.

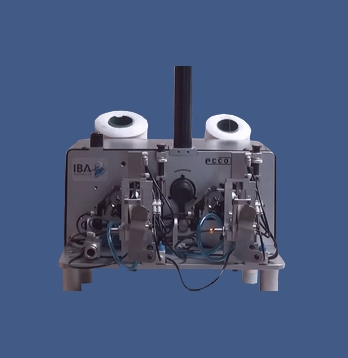

Machine ECCO III

ECCO II is the „little brother“ of the computer controlled SIGMA II. Even though it’s performance is not the same, ECCO II will produce high quality bobbins faster and, at half the cost of other mechanical winders. You will save money with lower maintenance cost, less personnel, less downtime on your production machines and less wastage. You may calculate a 60% higher productivity compared with conventional winders.

Technical Data SIGMA II

Maintenance:

free

Parameter settings:

with computer and manual

RPM:

1-2400 RPM variable

Production control:

length, diameter, form, thread break, tolerance, by computer and communication

Production data:

by computer, hours / 3 shifts/ total production

Production capacity:

12-14kg in 24 Std.

Main Motor:

230 V, 1-phase / 0.18 kW / 50/60Hz

Air Pressure:

6 bar

Technical Data ECCO III

Maintenance:

free

Parameter settings:

manuell

RPM:

1600 RPM fix

Production control:

by operator

Production data:

by operator

Production capacity:

7-9kg in 24 hours.

Main Motor:

230 V, 1-phase / 0.18 kW / 50/60Hz

Air Pressure:

6 bar

Production Video:

youtube.com

Retrofitting double shears

For the PitStop and the Schiffchen, you now no longer need to perform any steps manually. The ends are automatically trimmed for the PitStop/Schiffchen and can be fed directly into the PitStop/Schiffchen.

PProduction Video

Youtube

ECCO II

The best choise for the embroider and quilter.